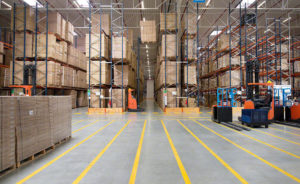

Enhancing warehouse storage effectiveness is a vital aspect of any manufacturing or circulation company. An obsolete, outdated warehouse workflow may affect an organization adversely, spending space and time which boost fees and reduces income. One must keep a regular observe over storage productivity to be able to disclose the total potential of the relevant organization. Even so, there appear to be issues in applying this sort of changes, because in a natural way employees are often hesitant to embrace alter.

Carton movement shelving is amongst the most overlooked warehouse storage methods that could boost effort productivity instantly. Because the newest inventory is loaded in the back end, the program not only makes sure to release the goods inside the purchase they arrived in the warehouse, but in addition decreases disturbance in between choosing and stocking personnel. Carton stream applied jointly with particular curler shelves causes it to be the supreme efficiency enhancement strategy for any kind of warehouse. Documenting your order designs of item in a deciding on system might be a useful physical exercise that assists in slotting the stock proficiently. For example, well-known products which possess a increased choose volume level ought to be slotted in the front conclusion of your decide on location for easy access and to decrease travel time. This method can be valuable if grouping or categorizing merchandise into one particular area fails to enhance effectiveness.

Simply being systematic and training the workers appropriately can also work amazing things. There exists a lot specialised information which will help a crew of warehouse employees to be more efficient in choosing and saving goods. If more treatment is considered to go through your order selecting demands to get a probable worker when enrolling, the efficiency in the 葵涌迷你倉 increases. Co-procedure and comments involving administration and warehouse workers produce an optimistic distinction in the functional achievement of the warehouse. Managing squander, problems, and eradicating mistakes are very important to sustaining a low fat successful operation. Shelving and storage should be nicely designed; supplying diverse structures and approach for quick, medium sized, and slow shifting supply. Purchase selecting operations should focus on minimizing travel time in between chooses and supply easy access to item in the select stage.

Preventing probable storage problems within their most straightforward kinds is a method to increase productivity. For example, if there are beverages piled in cartons across a rack of dried up meals, there is a storage defect. Such imperfections in warehouse storage may bring forth unanticipated disasters. Spotting very similar dangers is a way to avoid them, which in turn raises performance in the long term. When there is one essential thing to be aware of concerning storage, it needs to be sound judgment. If you find a well-balanced process whereby a higher amount of inventory coming in will not impact the picking process, it is likely because an efficient storage training into position.